with INSTANET Internet Generator

The Connected

Factory Revolution

IoT Integration for Smart Manufacturing

INSTANET Internet Generator seamlessly integrates with IoT devices, creating a smart manufacturing ecosystem. Real-time data exchange, predictive maintenance, and automated processes contribute to a connected factory revolution.

Unified Communication Hub

By transforming the manufacturing plant into a unified communication hub, INSTANET facilitates instant collaboration between workers, machines, and management. This interconnectedness is pivotal for agile decision-making and swift response to production challenges.

Smart Inventory Management

INSTANET empowers manufacturing plants with smart inventory management. RFID and IoT technologies enable real-time tracking of inventory, reducing stockouts and improving overall supply chain efficiency.

Revolutionizing

Intelligent Resource Allocation

Leveraging the power of INSTANET, manufacturing plants can implement intelligent resource allocation. Load balancing and failover mechanisms ensure that production lines run at optimal efficiency, minimizing downtime and maximizing output.

Predictive Quality Control

INSTANET enables predictive quality control by analyzing real-time data from production processes. This ensures early detection of defects, reducing waste and enhancing overall product quality.

Energy-Efficient Operations

INSTANET contributes to energy-efficient operations by optimizing machine usage based on demand patterns. This not only reduces energy consumption but also aligns with sustainability goals.

Innovations for the

Future of Manufacturing

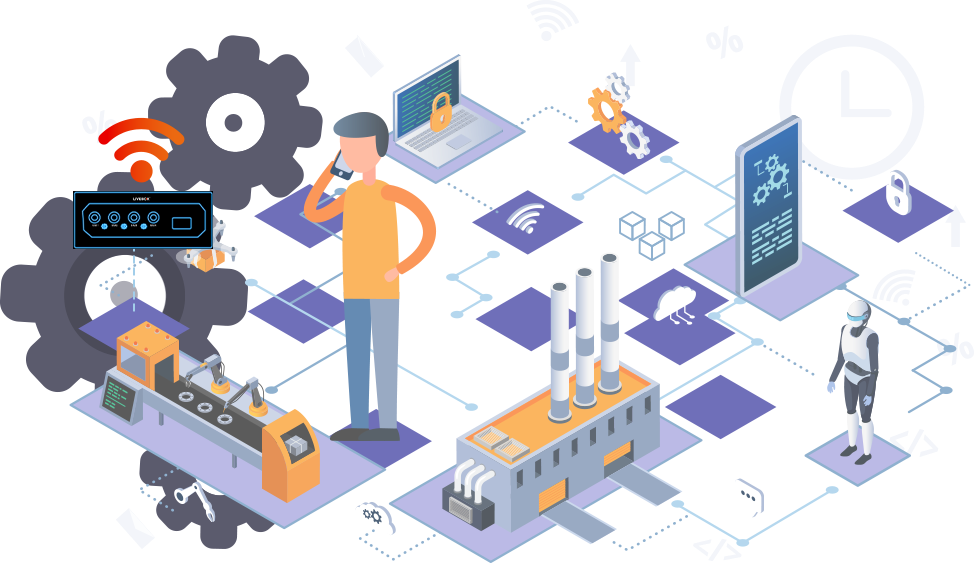

AI-Driven Predictive Analytics

INSTANET's roadmap includes the integration of AI-driven predictive analytics. This innovation will empower manufacturing plants to forecast potential issues, optimize processes, and make data-driven decisions for continuous improvement.

Robotics Process Automation (RPA) Integration

In collaboration with RPA, INSTANET aims to streamline repetitive tasks on the production floor. This integration enhances operational efficiency and allows human resources to focus on more complex aspects of manufacturing.

Blockchain for Supply Chain Transparency

INSTANET explores blockchain integration to enhance supply chain transparency. This innovation ensures a secure and transparent flow of information across the supply network, reducing the risk of fraud and errors.

Sustainability and

Green Manufacturing Practices

INSTANET contributes to green manufacturing by optimizing energy consumption. Efficient connectivity and streamlined operations reduce the overall environmental footprint, aligning with the industry's sustainability goals.

Waste Reduction through Data Analytics

By leveraging data analytics, INSTANET assists manufacturing plants in identifying areas of waste in production processes. This proactive approach aids in waste reduction and supports sustainable manufacturing practices.

Water and Resource Management

INSTANET extends its impact to water and resource management, helping manufacturing plants monitor and optimize water usage. This contributes to sustainable practices and ensures compliance with environmental regulations.

Realizing the

Custom Solutions for Unique Challenges

INSTANET understands that each manufacturing plant has unique challenges. Our team collaborates with plant managers to tailor solutions that address specific pain points, ensuring a customized approach to connectivity optimization.

Continuous Innovation Cycle

INSTANET commits to a continuous innovation cycle, staying ahead of technological advancements. This ensures that manufacturing plants always benefit from cutting-edge connectivity solutions and remain at the forefront of industry 4.0.

Employee Training and Skill Development

In addition to technological advancements, INSTANET supports manufacturing plants with employee training programs. Ensuring that the workforce is well-equipped to handle advanced technologies enhances overall operational efficiency.

Features of INSTANET

HDWAN Capabilities

INSTANET's HDWAN (Hardware Defined Wide Area Network) ensures a high-performance network connecting different plants and remote locations reliably.

Load Balancing and Failover

Distribute network traffic across multiple WAN links to optimize internet resources, and automatically reroute traffic to alternate connections in case of an outage.

Cloud NAT for Secure Communication

Overcome the limitations of private IP address ranges, facilitating secure device-to-server communication essential for remote management and updates.

Real-time Monitoring and Predictive Analytics

Monitor and manage IoT devices' connectivity from anywhere in real-time. Utilize connection data to predict and prevent issues before they affect the network.

Elevate Your

Join the manufacturing revolution with INSTANET Internet Generator. Elevate efficiency, embrace sustainability, and unlock the full potential of your plant's connectivity. Connect with INSTANET experts to embark on a journey toward manufacturing excellence.